ELECTRONICS PRODUCTION

Flexible, reliable, personal

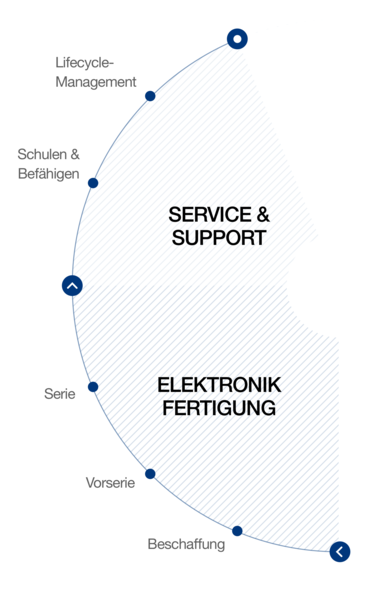

When the engineers have developed the hardware, it's all about the competent production of your module. We support you in this, regardless of whether your own or our experts have designed the system. Smooth interaction is crucial. Take us on board early and we will bring you effective added value for your success.

At hema, highly individual electronic components are created from a wide variety of parts with the competence of experienced and trained colleagues.

Production of top-quality modules

At hema, there is close contact between electronics manufacturing, purchasing and development. The entire production process thus benefits in full from the know-how of all departments. The close cooperation between the specialist departments at hema brings a real advantage to you as the client.

Making sophisticated industrial electronics available over the long term is our aspiration. hema's modern production is well positioned to reliably supply our clients with modules. Quantities of between 1 and 1,000 are manufactured to the client's specific requirements in both SMD and THT assembly. High mix and low volume production batches are the speciality towards which we have configured our production. At the same time, we have established ourselves globally on the procurement side in order to ensure long-term availability.

Our warehouse is stocked with millions of components, including more than 20,000 different types

Production-Know-how:

- SMD assembly

- THT assembly

- Soldering with lead-free or leaded solders, depending on the specification

- Assembly of modules and complete systems

- Commissioning with software

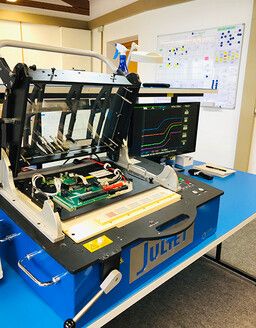

- Functional & endurance tests

- Quality control and documentation

- Test reports containing the serial number, version and revision information for traceability

Solder paste screen printer

SMD assembler

Screen printing and assembly in a flexible structure for fast prototype production and series with up to 1,000 units

Functional testing

Traceability via bar code

Automated function tests for devices and systems ensure their reliability

Material tracking and stocking ensure long-term availability

We support the reliable supply of your production with accompanying services that cover all aspects of procurement and production:

- Procurement, service and support over the entire product life cycle

- Traceability: full batch-based traceability

- Production of initial samples, prototypes, small series and medium series

- Systems assembly

- Obsolescence management

Key facts

Around 800 m² of floor space are given over to manufacturing, cleaning, testing and quality control of electronic circuit boards. In Production, a total of 20 our colleagues are working for you in the fields of production planning and control, SMD and THT assembly, device assembly and testing, quality management and logistics.

Your industrial electronics will be created to do the job that you want it to do for 10 years or more. We will make sure of that.

We are certified according to ISO 9001-2015

DOWNLOAD:

ISO 9001-2015 Certificate

We regard the highest IPC-610 Class 3 as standard. That's how we guarantee the best quality for your products. The average batch size of circuit boards is 75 units.