IMPLEMENT EFFECTIVELY

Designing future-oriented systems

Modular concepts, building block systems and platform technologies promise better development processes and ultimately more successful products. Is that the formula for success?

Why this works perfectly with embedded vision systems is explained here.

"Being on the market at the right time" - this is the big challenge most often mentioned for the success of products. In technology markets, the time from the idea to the implementation of the finished product is therefore usually also decisive. When opportunities are recognized, it is important to place suitable solutions as quickly as possible before the competition. This is exactly where we support our customers.

The proven hema Vision platform and well-established design processes accelerate development and lead to well thought-out systems with high customer benefits.

"Enter the ecosystem - outpace competition - thrill your customer!"

As a specialist for embedded vision systems we dedicate our time and energy to this special field.

Our customers use the embedded vision platform for:

- Industrial Vision: Visual intelligence for roboter, cobots and automation

- Rough & Tough: Situational awareness in avionics, defence and safety

- Mobile Vision: Conscious movement in mobile applications for transport and infrastructure

- Medical Imaging: Visual intelligence for your health

- AI Solutions: hardware acceleration for artificial intelligence

The "3 levels model"

About the interaction of hardware, IP and software in an embedded vision solution.

LEVEL 1 - Hardware

The hardware ensures the connection of sensors and signals to the system. Interfaces, power supply and processor technology are combined here and provide the basis for intelligent latency-reduced video processing.

Example: Video inputs for analog and digital signals lead the video channels to the FPGA. There they are processed by the software and then transferred to the appropriate users.

LEVEL 2 - Software and IP

To be able to recognize situations, a large amount of data must be evaluated and compared. The sensor data passes through a variety of image processing software packages (superimposition, compression) to prepare the captured scenes.

Example: Sensor fusion of lidar, TOF and day vision cameras for the detection of persons and objects. The images are processed, superimposed and receive graphic overlays.

LEVEL 3 - Software and Application

The customer application is the face of the system. The user or the automatic system interacts with it. He or she receives the information generated by the system from the large amount of data and can act according to the situation and task.

Example: Recognition of persons and objects, transmission of coordinates and information, and subsequent classification into categories that trigger appropriate actions.

Modular in use for your project

Development projects require suitable hardware in each project phase.

- as design environment

- as a prototype

- as standard product

For each phase there is a suitable variant of how you can use processor modules and vision mainboards. With numerous FPGA modules from the manufacturers Enclustra and Xilinx, we ensure that the electronics match your requirements for performance, functionality and interfaces. Brand new and as the first manufacturer worldwide, we also offer mainboards for the new Xilinx Kria SoM family.

We will be happy to advise you on the perfect embedded vision system for your application. Talk to us about your project:

Torsten Schairer

Head of Sales

E-mail: t.schairer (at) hema.de

Phone: +49 7361 9495-16

In 6 weeks to sustainable electronics.

From the idea to the close-to-series prototype of your embedded vision electronics in just six weeks: In our latest webinar Oliver Helzle talks about how this works, about the advantages of modular design with the hema Embedded Vision Platform and why the combination of individual mainboards and System on Modules is both future-proof and economical.

Whitepaper

Faster Time to Market, lower Design Risk

Adam Taylor of ADIUVO Engineering and Training, engineer and Fellow of the Institute of Engineering and Technology, and Oliver Helzle, Managing Director of hema electronic, combine their knowledge and experience in embedded vision hardware design in this white paper. It covers the basics of electronics development with System on Modules and modular hardware.

--> Download:Faster Time to Market, lower Design Risk

Modular approach for the design environment

Nowadays, the main effort of many development projects in the field of embedded vision is the development of software for image processing and machine vision. When considering the project effort, it is important to plan these large work packages ideally into the project duration. In order to get the software development off to an optimal start, it is recommended to build up near-series hardware early on, which is then available as a basis for development. The closer to the planned system, the more targeted the software can be developed.

One variant is the use of evaluation boards from the manufacturers. More effective, however, is the use of an industry-compatible, proven platform that can be designed and built in a modular fashion. With this preliminary work, a mature basis is created at the beginning of the project, which reduces later adaptations and can accompany the project in the long run and grow with it. This is ensured by the mainboard and module approach of hema.

Recommendation: Embedded Vision Platform

Fast to the prototype

In the second phase, prototypes of the target hardware are required as part of the development. Here again the modular platform and the use of modular technology can be used. In most cases, the platform already meets all requirements (functions, interfaces, ...) and can be used flexibly as a test bed in agile design processes. Adaptations on the mainboard and the selection of a module with other properties can be realized very quickly. This means that software development can rely on an existing technology.

An alternative in the prototype phase is the construction (design-in) of a customer-specific version, which connects the mainboard with the module. This allows individual requirements (design, number of interfaces) to be implemented in the system environment.

Recommendation: hema Fastlane Boardservice

Hardware for series

There are three possibilities for the use of mainboard and module. As in the development and prototype phase, it is possible to continue working with the module technology. The mainboard can be customized and the software can continue to run on the module.

The second variant is the design-in of module and mainboard into an individual variant for the customer project. This ensures that target prices and installation specifications of the end product are met.

The third option is the redesign of the module adapted for the customer from the prototype phase. This meets the defined requirements of the series system.

Recommendation: hema Modul platform and manufacturing services for series production

Regardless of the phase in which you decide on which variant - hema, as a full-service provider with development, module technology and procurement as well as production, provides you with competent support at all times.

Faster to market for long-term success

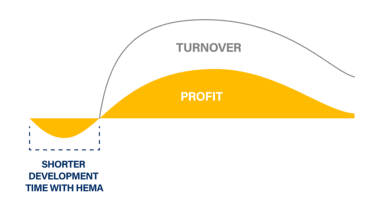

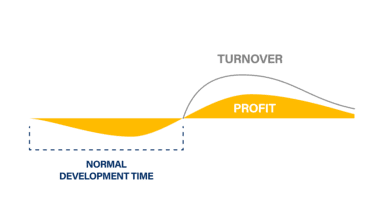

How this approach will have a positive effect on your project: We show you how to optimize development time, budget and time-to-market.

The classic life cycle curve provides for the steps product development, market entry, growth phase, utilization phase and market exit. With the platform approach we actively influence the time and outcome of this process. The use of a development platform shortens the development period, reduces effort and thus costs and ensures earlier market entry.

The lead over the competition is decisive: Being in the market earlier means occupying this position and placing your own product ideally "status as innovator". Being on the market earlier also secures a larger market share. This results in an economically advantageous position on the market.

And if, based on the modular platform, the products are provided with performance-enhancing updates during the product life cycle, the service life and the attractiveness of the product on the market are secured for longer. With a small effort, such as replacing the module, a much longer use is possible. The development costs are thus significantly lower than for a new development. This increases the economic efficiency.

If the extended service life of the product comes to an end on the market, the platform system enables a successor product to be placed on the market in good time. This can then be offered on the market again with reduced effort and quickly before the competition.

This repetitive cycle reliably leads to long-term success on the market.

More information about our projects and the FPGA module world can be found here: