SYSTEM OVERVIEW

The compact camera for the robot

The seelectorICAM camera family combines high computing power with a highly dynamic CMOS sensor. Sharp vision with up to 170 dB dynamic range, fast image acquisition with global shutter, high resolution!

seelectorICAM comes as a full-fledged image processing system in compact format. It is now possible to evaluate the weld seam in the welding process under highly overexposed and inhomogeneous lighting conditions.

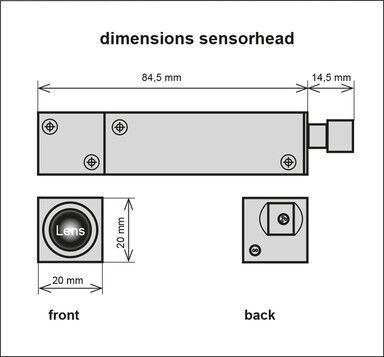

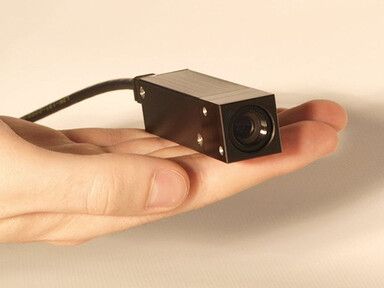

For applications that require a particularly small camera, there is a version with a miniaturised seelectorICAM HD4 sensor head.

This provides the right camera for different space conditions.

The completely new approach in industrial image processing: The seelectorICAM camera family combines high computing power with a highly dynamic CMOS sensor.

Sharp vision in extreme lighting conditions, fast image acquisition with global shutter, high resolution! seelectorICAM comes as a full-fledged image processing system in compact format.the extremely small sensor head is ideal for mounting on robots. It is well protected with protective glass and, if required, with a protective housing. The embedded computing unit for evaluating the image data is mounted in a suitable position.

SPECIAL FEATURES

Komponenten

The miniaturized sensor head has room everywhere. It is small, light and is mounted metres away from the camera CPU - ideal for robots or tight spaces!

APPLICATIONS

The compact and robust design of the camera (200 x 50 x 50 mm) is designed for use in difficult environmental conditions.

This visualization solution for welding process monitoring is supplied by hema to the user as a package "seelectorICAM weld". It contains all components including connections and cabling as a "plug & play" system.

Our seelectorICAM weld HD4 was developed for use in robotic applications in extremely confined spaces. Machining processes in hard-to-reach positions are tracked and made visible.

The new seelectorICAM weld HD4 with GigE-Vision and image processing software based on HALCON standards enables manual or automated analysis and measurement.