For the development, production and customer-specific adaptation of SoM concepts, external service providers require in-depth know-how, tact and an open ear for the customer's requirements.

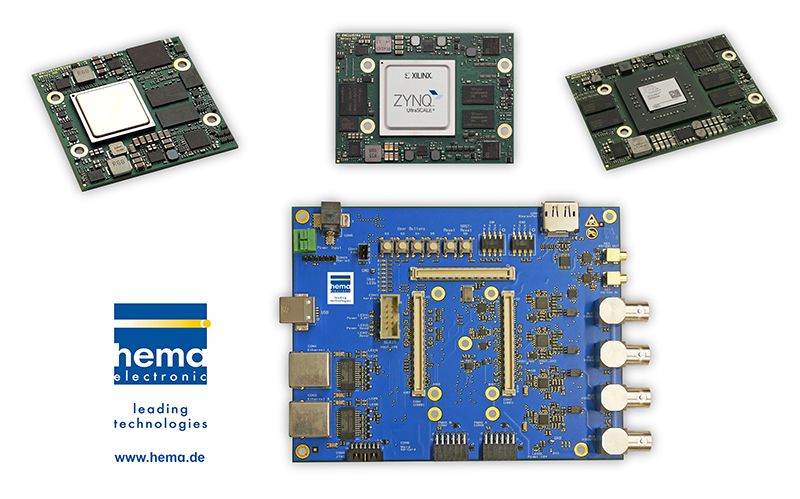

Electronic assemblies according to the System-on-Module concept (SoM) contain processors, DDR and flash memory, communication interfaces and have a power supply. A large number of I/O pins are provided via board-to-board connectors. In conjunction with the mainboard, which contains the application-specific interfaces, this creates a wide range of possible uses.

In order to be able to offer and implement such systems for their customers according to their needs, external service providers must have a great deal of experience in development and production processes. Particularly in the development area for the mainboard, listening and thinking carefully is very important. Only then are external developers and layout designers able to translate their customers' wishes into perfectly functioning and optimally adapted systems.

A major advantage of using SoM in combination with a mainboard is that the mainboard only has to be developed once. The modules can be replaced by more powerful models after a certain period of time, depending on your needs and increased requirements. However, the mainboard remains the same. Thus a once developed and tested system remains available for a long time.

In many industrial companies it is common, or simply necessary for reasons of capacity and existing infrastructure, to outsource individual work steps in the development of embedded systems to external service providers. These have the infrastructure and expertise required for the development and production of modules. Customers do not have to deal with process steps that are hardly known internally, but can rely from the outset on the fact that the supplier's services are characterized by a high level of employee competence and have been successfully tested for years.

It should be a matter of course for service providers in electronics development to be familiar with the applicable regulations for different industries. Knowledge of trends, especially in times of increasing digitalization, is also a prerequisite for promising services.

Some companies rely on flexible freelancers when looking for external support. These can be used for project tasks in the event of capacity bottlenecks - however, a service company with a permanent staff usually provides more reliable support and further development. There, the employees already have a sound knowledge of the customer's company through many years of service. Service companies offer sufficient resources of their own to take over tasks for their customers for a limited or even long-term period of time and the staffing level is often the same for years.

Just as important as technical knowledge, sufficient personnel resources or existing infrastructure is an open ear for the concerns of the customers and a transparent way of communication. It makes it much easier to process orders if regular updates and reviews are carried out together with the customer. The basis for a common understanding is created by the long-term cooperation with a service company. In this way, coordination and approvals between client and service provider can be carried out quickly and smoothly. Earlier project completion enables an earlier market entry, and this gives the customer a decisive competitive advantage.

Embedded vision experts like hema electronic have trained specialists with a lot of know-how. The Aalen-based company supports its customers both in electronics development and in production. In addition, hema's corporate cooperation with Enclustra - the Swiss specialist for FPGA modules - ensures that competencies are bundled into modules and mainboards. The jointly successfully established platform system illustrates this.

In-house production, an ISO 9001 certified quality management system, the assumption of complete project management including cost control and life-cycle management for subsequent production, as well as the enthusiasm of the entire team for electronics have been fulfilling small or large, standard or very special customer wishes for over 40 years.