SICHTBAR SICHER

Qualitätssicherung im Schweißprozess mit intelligenten Kamerasystemen

Sie wollen Ihre Produktivität erhöhen? Die Bearbeitungsqualität in Ihrer Fertigung verbessern und die Nacharbeitsquote verringern? Sie wollen die Durchlaufzeiten senken? Sie wollen die Arbeit erleichtern und beschleunigen durch den Einsatz neuer Technologien? Sie wollen automatisieren und selbststeuernde intelligente Prozesse etablieren?

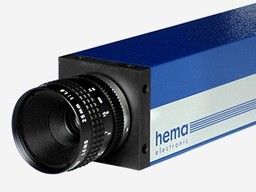

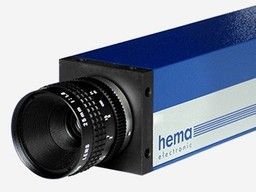

Das intelligente Kamerasystem seelectorICAM weld von hema electronic für die Visualisierung von Schweißprozessen unterstützt Sie, diese Ziele zu verwirklichen. Wir bieten Ihnen erprobte Systeme, kundenspezifische Entwicklung und industrielle Bildverarbeitung auf höchstem Niveau.

WIG-Schweißen

Microplasma-Schweißen

Plasma-Pulver-Auftragsschweißen

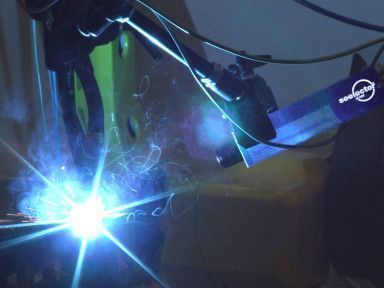

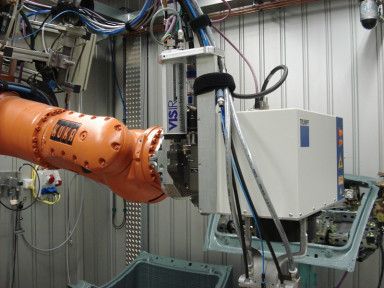

"Weltklassebilder" bis ins Detail – unterstützen die Optimierung von Schweißprozessen, Schneideprozessen und Lasermaterialbearbeitung

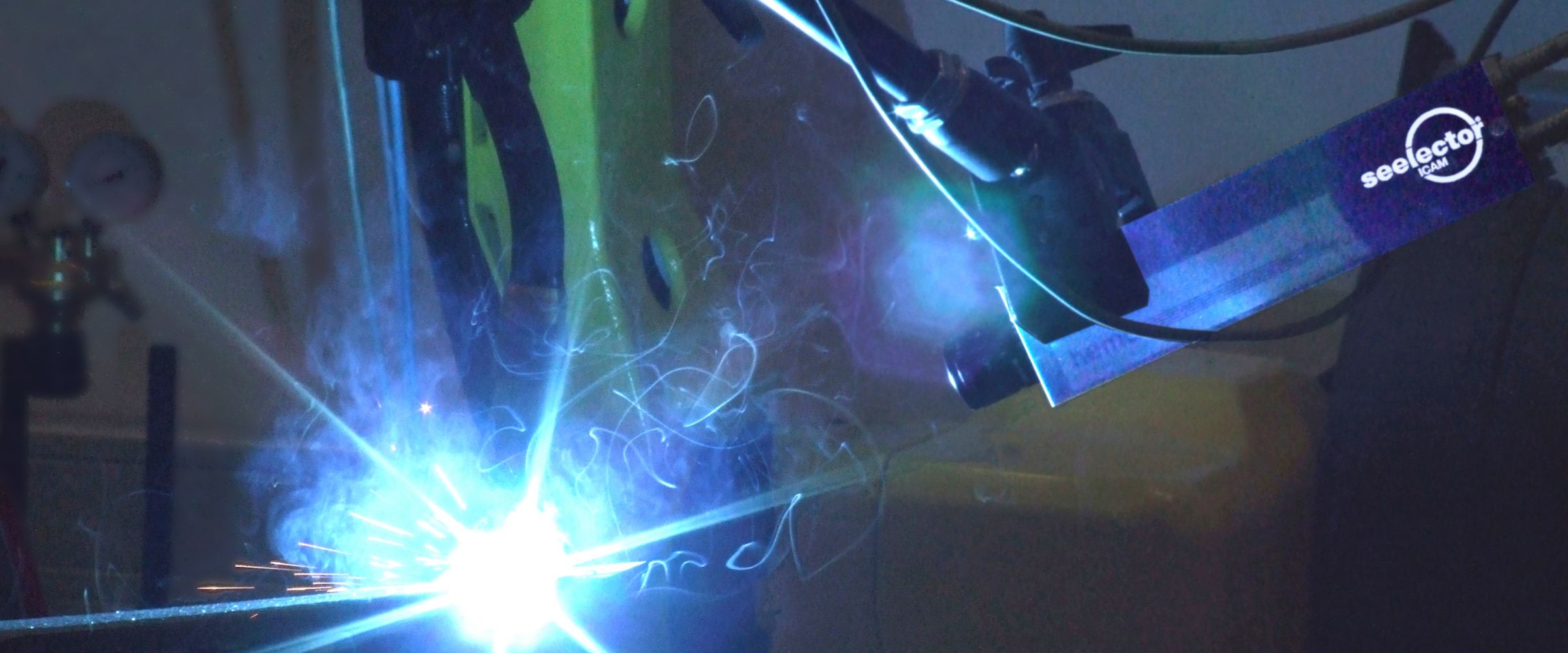

seelectorICAM weld an der Schweißanlage

seelectorICAM LASER in der Laser-Materialbearbeitung am Roboter

Qualitätssicherung beim Schweißen bedeutet:

- Optische Kontrolle am Monitor. Damit ist der Werker entlastet oder sogar Personal eingespart, weil mehrere Kamerabilder zeitgleich von verschiedenen Positionen angezeigt werden.

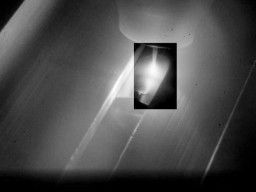

- Automatisierte Funktionen mit Industrieller Bildverarbeitung. Spaltsuche und Vermessung, Überwachung des Schweißbads, Vermessung der Schweißraupe, Analyse und Vermessung der Wärmespur - das alles ist möglich!

- Sonderlösungen für Spezialaufgaben, wenn eine Aufgabe besondere Anforderungen stellt, z.B. mit hohen Sicherheitsanforderungen, schwierigen Platzverhältnissen oder bei sehr hohem Automatisierungsgrad.

Unsere Kamerasysteme führen Sie zum Erfolg:

- 100 %-Kontrolle jeder Schweißstelle live

- Betrachten des gesamten Helligkeitsbereiches ohne Überblendung "macht jedes Detail sichtbar"

- Ermittlung der Schweißparameter zur optimalen Steuerung des Schweißprozesses

- Dokumentation mit Videoaufzeichnung

- Roboterschnittstellen für die direkte Ansteuerung

Wir stellen Ihnen gerne dieses industrietaugliche Kamerasystem in Ihrem Haus vor.

Unsere intelligenten Kamera-Systeme für Ihre Anwendungen

Mehr zu unseren Videosystemen und ihren Anwendungsgebieten finden Sie hier: